|

Program Manager, Decommissioning

|

Arnaud Du Bois: I’m the Program Manager - Decommissioning at Tractebel, so I supervise Tractebel’s activities related to the decommissioning of the nuclear power plants, Doel and Tihange. I also represent Tractebel in the Decommissioning Management Team of Electrabel. The program currently involves more than 250 full-time equivalents within Tractebel. |

|

Project Manager, Demolition

|

Kurt Van Stappen: I‘m an expert in decommissioning, including asbestos removal, and the deconstruction and demolition of industrial installations and power plants to return the sites to brown- or greenfields. Within the Rehabilitation of Industrial Sites (RIS) team, I’m responsible for the services, demolition and asbestos removal for the geographical areas of Flanders (Belgium), the Netherlands, Germany and the United Kingdom. As the Project Manager - Conventional Demolition, I’m in charge of decommissioning and demolishing the conventional (non-nuclear) buildings and structures of the nuclear power plants in Belgium. To give a concrete example, I am looking for the best method (in terms of safety, planning and budget) for the demolition of the cooling towers by investigating the working conditions and studying the market and projects already carried out on other sites. |

You both say that you work on the decommissioning of nuclear power plants. What is that exactly?

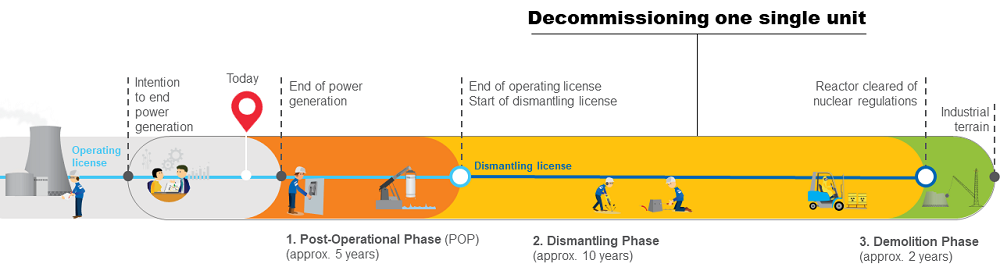

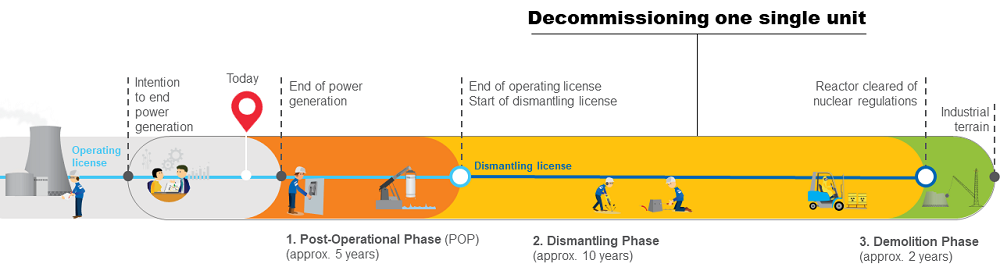

Arnaud: Decommissioning is the final phase of the life cycle of a nuclear power plant after construction and operation. It consists of safely removing all radioactive materials in the facility, and preparing the site for new industrial or non-industrial uses. It includes all the administrative and technical measures taken from the decision to shut down the reactors until the site is returned to a greenfield.

Around 100 projects need to be carried out to stop the plant safely, transfer the spent nuclear fuel to another installation on-site and start the decontamination and deconstruction of the equipment and buildings. The materials that are generated are characterized and sorted between nuclear and non-nuclear. Non-nuclear materials will be treated as other demolition waste (recycling, etc.…) while the radioactive materials will be safely transferred to ONDRAF/NIRAS, the Belgian radioactive waste management agency.

Kurt: Compared to the decommissioning of other industrial sites, nuclear ‘decommissioning’ is quite specific as it covers everything from the preparation of the installations’ deactivation, and the asbestos removal to the final dismantling and demolition. The decommissioning of the Belgian nuclear fleet is by far the most complex project in Belgium’s history due to the nature and scale of the activities. In my experience, the average duration of the decommissioning, demolition included, of a large-scale power plant is two to three years. The decommissioning of a nuclear power plant takes much longer, over 20 years, which shows how complex and large the project is.

Arnaud: A decommissioning program is indeed a long-term project (over 20 years) from the preparation phase that starts several years before the end of power generation, the post-operational phase that lasts 3 to 5 years, the nuclear dismantling phase (around 10 years), to the conventional dismantling phase (around 2 years) until the site is returned to a conventional industrial area.

The dismantling of one reactor (e.g. Doel 3) generates around 360,000 tons of materials and waste, of which 99% will be recycled, reused, or disposed of in a conventional way, 1% will be managed as short-lived radioactive waste for surface disposal (Category A), and 0.02% as long-lived radioactive waste for geological disposal (Category B).

A longer timeframe is required to manage long-lived radwaste. This type of waste will be stored for a few decades in Dessel in a storage facility. It should eventually be disposed of in a deep geological repository, which has been recently confirmed by the Belgian government.

©ENGIE Electrabel

What is the most challenging in a decommissioning project?

Kurt: Delivering the project on time and on budget requires a high level of competences and skills. The safety aspect is also crucial, and one of the most challenging. The safety of the workers and the public is ensured by evaluating the consequences of potential hazards and considering how to mitigate them.

Given the scale and complexity of the project, coordination and communication with many stakeholders are also key. Moving from the feasibility studies to the detailed design and execution will be also very challenging. We need to take care to involve highly skilled and experienced professionals for the projects to be successful. The decommissioning of a nuclear power plant represents a lot of technical challenges but also human, regulatory, social, and societal challenges.

Arnaud: The decommissioning of a nuclear power plant represents a lot of technical challenges, one major being the removal of radioactive waste. Several components have been strongly activated or contaminated during operation and need special attention. For example, the removal of the control rods and other non-fuel components in the deactivation pools require the set up of specific inventorying, characterization, segmentation, and packaging techniques. This critical activity is furthermore rendered more complex by the absence of clear and stable Waste Acceptance Criteria impacting constant changes on the project requirement.

What are the benefits of nuclear decommissioning to society and the environment?

Arnaud: As the operator’s engineer and the architect engineer of the Belgian nuclear power plants, it is our responsibility to support Electrabel to decommission them in a safe and environmentally friendly way. We are committed to returning the sites to a “greenfield” status for future generations.

Radwaste management and decommissioning are also the main hurdles to public acceptance of nuclear energy. Demonstrating that it can be done in a safe, environmentally friendly and cost-efficient manner is the best way to change people’s and especially policy makers’ minds and to foster investment in new low-carbon nuclear capacities.

Why did you choose this specialization?

Kurt: It’s a boyhood dream: being able to demolish things and get paid for it! But of course, to me, it is above all an opportunity to contribute to a clean-energy future.

Arnaud: We face different kinds of challenges in the decommissioning activities. As an engineer, it’s thrilling to constantly have to find innovative solutions to tackle them. It gives me the opportunity to develop my technical know-how by exchanging with our experts. It also enhances my managerial skills by interacting with the different stakeholders. I also feel empowered and motivated by the societal dimension of decommissioning. Helping solve the issue is extremely rewarding. Finally, I am proud to be involved in one of the largest industrial projects in Belgium.

What do you like about your job?

Arnaud: As Tractebel Program Manager and member of the Decommissioning Management Team of Electrabel, I play a central role in steering the strategy, governance, and organization of the program. I like having a ‘helicopter view’ of all the program’s activities. It enables me to help the different stakeholders to understand the program’s challenges and their specific contribution.

I’m also interested in the innovation aspects. Several innovative technologies have been developed or are under development to support the decommissioning activities. They include advanced modelling and calculation tools and enhanced data management capabilities. The use of robotics, drones and automation is also under consideration to increase safety and efficiency.

Kurt: I love the versatility. As we are involved in very large and challenging projects, we touch upon different areas of expertise. We are at the crossroads of new projects. We say goodbye to old structures and buildings and look to a new and promising future.

It’s a great opportunity for me to use my pragmatism to carry out such a large-scale project. My role is not only to decommission all the installations but also to prepare the demolition strategy for the conventional buildings. My role is to ensure the projects are completed successfully.

Given the complexity and scale of these projects, it’s crucial to involve all the stakeholders in the decision-making process.

Interested in a career in the Nuclear sector? Discover our opportunities!